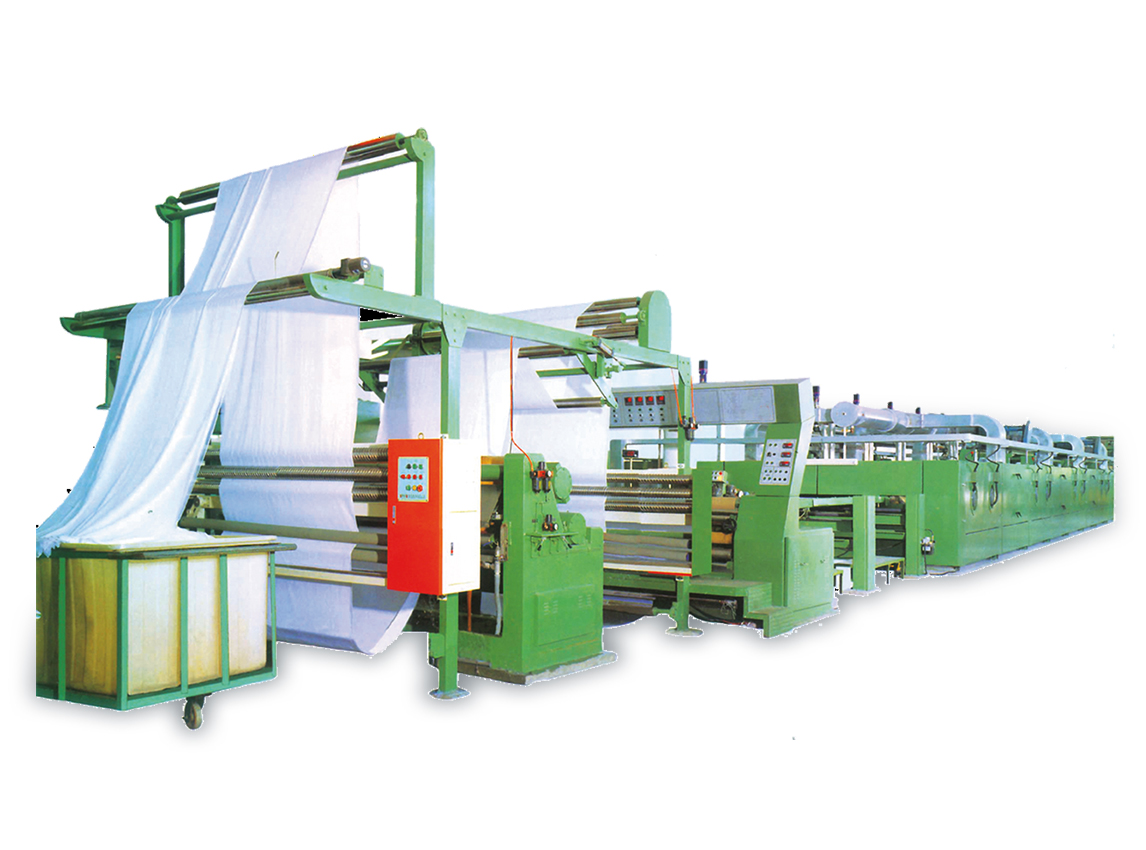

High efficiency hot stenter setting machine

The left and right brush feeding by AC frequency conversion motor, through the special type inkage proportion seting set feedbackcontrol instrument, in a closed loop retum to accurately control feeding system, ensure the feeding quality stability. And the use oihumanized type code compression control, convenient operation and adjustment and beautiful. Hot air circulating system adopts a specialwind delector structure,fan motor with variable frequency control, so that uniform temperature airflow comprehensive fabric, enhance theoualitv and feel of cloth, The exhaust fow desion and wind circulating svstem as the best proportion. to ensure that the oven temperatureuniformity, the eficient use of enerav, Science and technoloav of dicital management concepts. combined with the exhaust control machinecloth stereotypes, cuality recuirements. fully automated control of oven and exhaust humidity, so that the most cost-effective unit enerqcost.

main technical parameter:

- working width:1200-2800mm

- mechanical speed:10-100M /min

- working temperature: the highest temperature is 220degrees Celsius

- the heat and energy consumption: steam heating, oil heating, gas heating, electric heating (108 kW / day )

- the tenter form: cloth clip or needle plate optionally

- feeding range:

a. Cloth feeding on feeding range – 10–30%

b. Needle brush feeding range of + 30%

c. A cloth feeding range of 30%

Related Products

Aqueous ecological synthetic leather production line

Agueous ecological synthetic leather production line is yuan hung machinery co. ltd new d…

Superfine fiber synthetic leather production line

Superfine fiber synthetic leather in terms of technology is combined with mulilayer proce…

PU、PVC dry production line

Dry synthesis of skin of PU resin coating method is coating in various lines of the relea…

PVC foam production line

Blowing, drying, shaping, can also be equipped with adhesive, coating, such as impregnati…